The RAPpro™ is a 100 T.P.H. hot mix asphalt plant specifically designed to efficiently produce high quality HMA utilizing 100% RAP. This plant has a revolutionary multi-tube in-direct heated, continuous flow Patented design. When coupled with PelletRAP™ rubberized binder additive used as a RAP rejuvenator and mix modifier extremely durable, high quality mixes are produced.

This is not a reconfigured or modified standard type hot mix plant. We’ve truly reinvented the way HMA is produced. The RAPpro’s energy efficient, stainless steel indirect heating and mixing design produces hot mix in an environment free of excess oxygen to help minimize further ageing of the RAP binder, and eliminating blue smoke typically generated by conventional plants when RAP content is too high. This unique design also removes the need for a bag house and heated liquid asphalt storage tank, so both the physical and emissions footprint of the RAPpro are greatly reduced, thus helping to ease any permitting requirements.

To produce a high performance hot mix with 100% RAP, as well as with virgin mixes, requires an engineered approach that focuses on the materials, binder and mix design. By using the Balanced Mix Design (BMD) method you use volumetrics as a tool, rather than a requirement. This allows you to design a mix with the greatest resistances to rutting and cracking.

Each ton of HMA produced with a RAPpro is rubber modified hot mix made with the PelletRAP additive, a unique pelletized material that is transported and stored at ambient temperature. While most rejuvenators just soften the aged binder, PelletRAP modifies it with a high quality PG binder blended and reacted with very fine crumb rubber made from recycled scrap tires and other light end additives specifically designed to revitalize badly oxidized pavement by restoring the viscoelastic properties of the aged binder. The rubber modified binder also allows for an increased optimum binder content without drain-down, bleeding or rutting providing an increased film thickness on the aggregate so is more forgiving with variations in the old RAP binder.

With the right equipment, proper material preparation, a high-quality rejuvenator and using the balanced mix design method you can produce asphalt mixes with 100% RAP that perform as well, or better than traditional mixes.

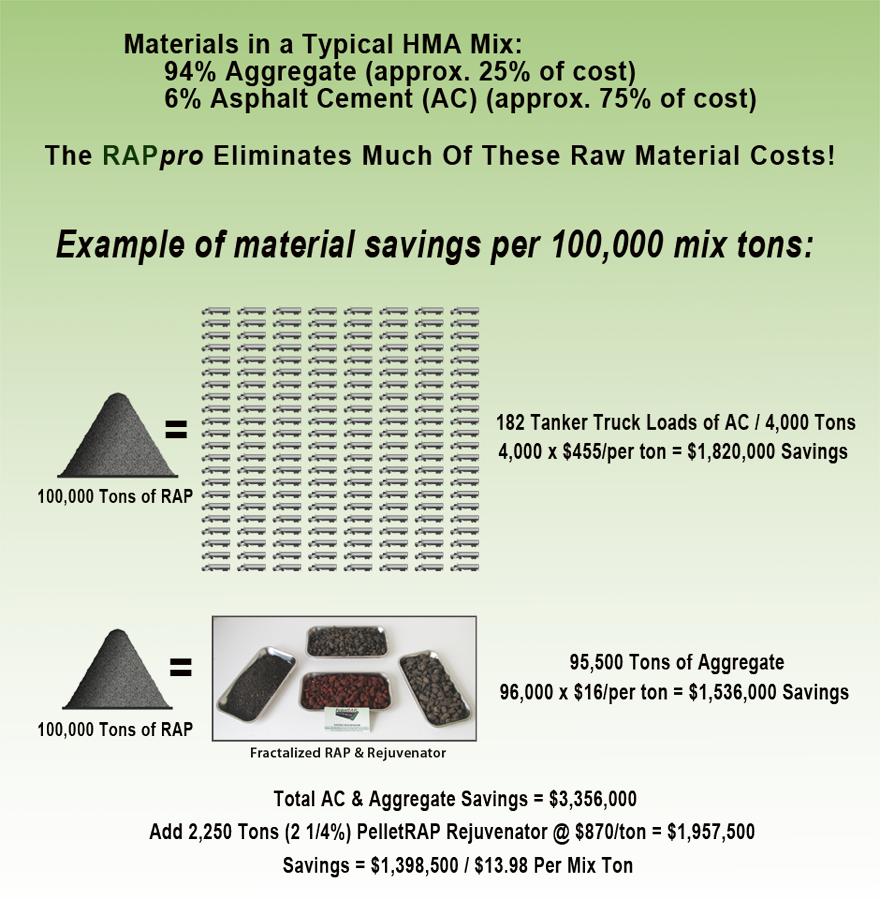

Hot mix produced by a RAPpro plant has the lowest carbon footprint of any asphalt pavement being produced. We refer to it is as "Double Green Pavement". By utilizing 100% RAP, this eliminates the need for virgin aggregates, thus saving a precious natural resource and the enormous amount of energy that would have been needed to process and transport this product to a hot mix plant site. In addition, the asphalt cement (AC) coating the RAP is reused. This greatly lowers the amount of new AC that must be refined, transported and stored at elevated temperatures.

The extremely energy efficient heating system of the RAPpro plant is another big factor in lowering carbon emissions. Its Patented design heats only the hot mix being produced, whereas with a conventional drum mix plant a huge airstream is heated, passes through the mixing drum to heat the aggregate and is then discharged from the plant into the atmosphere.

Also, with a RAPpro plant reusing the AC from the RAP material, along with the PelletRAP rejuvenator there is no need to have a heated asphalt cement storage tank. With a typical hot mix plant a huge quantity of AC is stored at or above 300°F twenty-four hours a day. This heating consumes a large amount of energy and VOCs are constantly being released from the hot AC.

By combining the use of 100% recycled asphalt pavement, crumb rubber derived from recycled scrap tires and the energy efficient production process of the RAPpro we are leading the Double Green Pavement Revolution….

Our parts and field service personnel are highly trained and have the resources to help our customers get their plants running and keep them running at peak performance.